- 22

- 6月

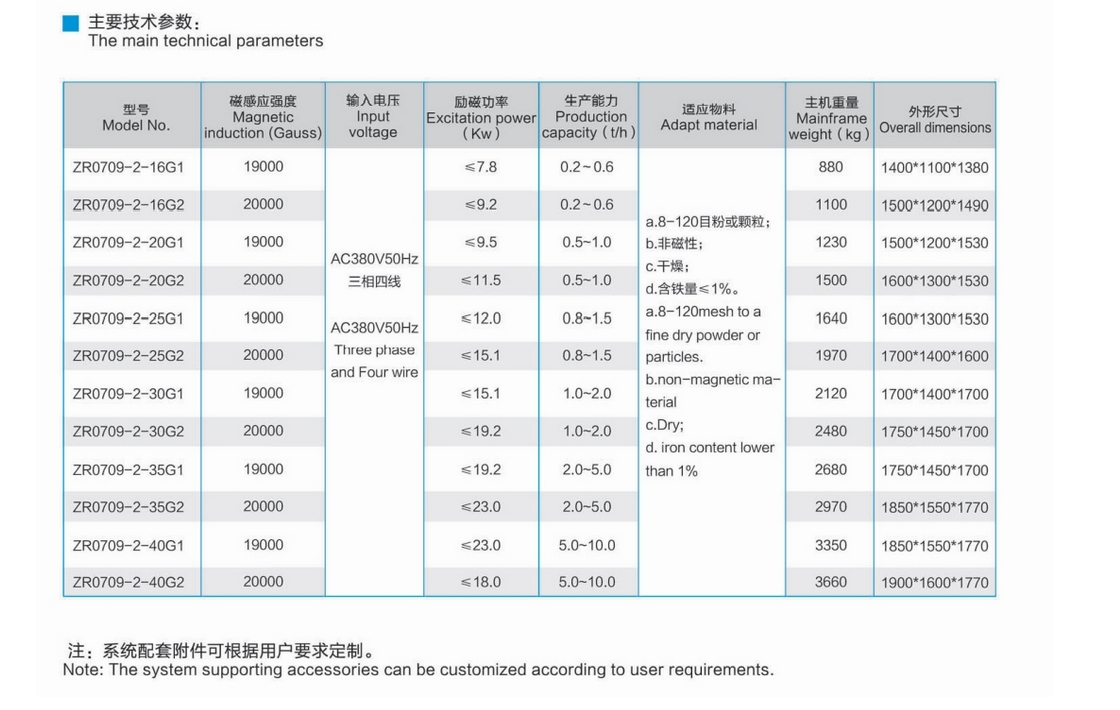

ZR0709-2-G series of electromagnetic iron separator for high purity dry powder processing

Overview:

The ZR0709-2-G high-purity powder magnetic separator is designed by our company’s scientific research personnel to meet the requirements of high-purity powder enterprises. Based on the principle of removing iron from the ZR0709 series electromagnetic powder separator, the coil structure is optimized by increasing the number of coil turns. , Compress the magnetic field space, strengthen the heat dissipation capacity and other technical measures to obtain a magnetic field with higher strength, greater gradient, and more uniform radial distribution; at the same time, the length of the magnetic cavity is lengthened, the magnetic separation process is increased, and the effect of iron removal is reduced as much as possible The unfavorable factors to obtain a more ideal iron removal effect. This machine is especially suitable for enterprises that have particularly high requirements for iron removal. We can provide a variety of models for users to choose.

Performance characteristics:

1. Unique design, the magnetic induction intensity of the medium mesh in the working cavity is as high as 18,000 to 20,000 Gauss. The honeycomb magnetic conductive medium is used as the magnetic carrier, which has a significant iron removal effect and high cost performance;

2. It is convenient and fast to clear the iron, and it only takes a dozen seconds to complete an iron discharge;

3. The forced oil circulating water cooling method is adopted, and the cooling effect is ideal;

4. During the working process, the magnetic cavity is in a state of vibration to ensure smooth material passing;

5. Take measures such as vibration reduction and noise reduction to ensure stable operation of the equipment and low noise;

6. With real-time temperature monitoring and automatic control functions, when the oil temperature rises to the set value, the system will automatically alarm until it stops, thereby effectively avoiding the coil from burning due to excessive temperature rise;

7. The fully automatic type adopts PLC intelligent control to automatically complete all actions such as excitation, feeding, and iron discharge without manual operation, reducing enterprise operating costs, and effectively avoiding human factors that affect the effect of iron removal. The color touch screen is used to set parameters, touch buttons to operate and display working status, and is equipped with a manual operation panel, which is technologically advanced and user-friendly.