- 23

- 6月

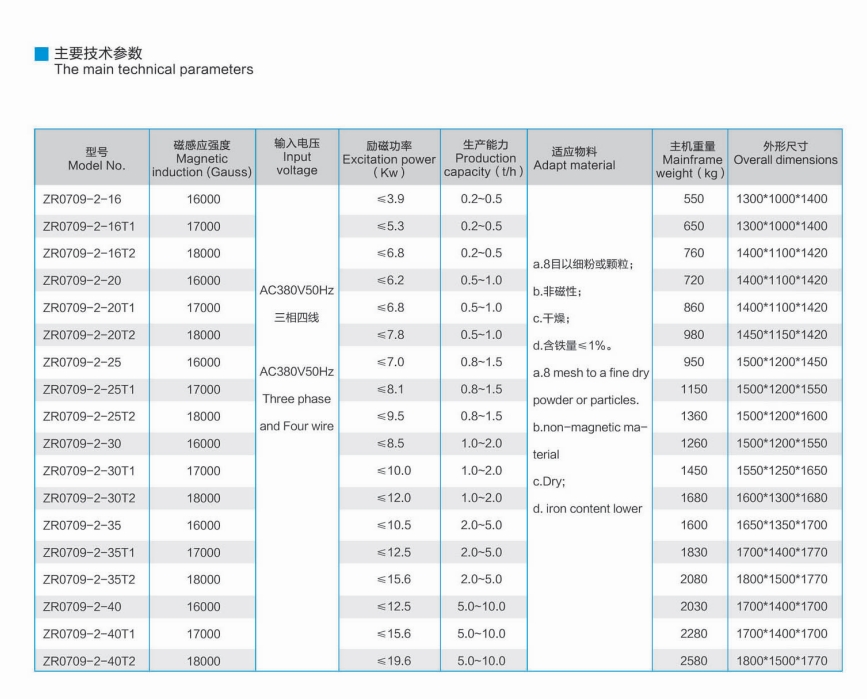

ZR0709 series dry electromagnetic powder separator

Overview:

With the continuous improvement of the requirements for the purity index of powder materials in the field of materials at home and abroad, the iron removal and purification treatment of powder materials has become an urgent problem in these industries. Due to the particularity of powder materials, the iron removal effect of many iron removal equipment has been unsatisfactory, and the cleaning is troublesome, which cannot meet the requirements of enterprises. After years of exploration and research, our company has successfully developed a cost-effective ZR0709-2 series of dry electromagnetic powder iron removers on the basis of drawing on foreign advanced technology and combining the requirements of domestic enterprises for the use of iron removal equipment. The machine has a unique design, high gradient, strong magnetic field, magnetic field strength as high as 18,000 to 20,000 Gauss, strong suction force and strong catching power. It can not only basically remove magnetic materials such as mechanical iron mixed in the powder processing process, but also generally remove iron. The iron oxide (Fe203) and other weakly magnetic impurities in the raw ore that are difficult to remove by the equipment can also be removed, and the iron removal effect is significant. The machine is convenient for iron removal, and it only takes ten seconds to complete the iron discharge; the machine can be used alone, or multiple units can be used in series or parallel to achieve the purpose of further improving the iron removal effect and improving the processing capacity. It provides an ideal solution for companies that want to improve product quality and grade.

Performance characteristics:

1. Unique design, the magnetic induction intensity of the medium mesh in the working cavity is as high as 18,000 to 20,000 Gauss. The honeycomb magnetic conductive medium is used as the magnetic carrier, which has a significant iron removal effect and high cost performance;

2. It is convenient and fast to clear the iron, and it only takes a dozen seconds to complete an iron discharge;

3. The forced oil circulating water cooling method is adopted, and the cooling effect is ideal;

4. During the working process, the magnetic cavity is in a state of vibration to ensure smooth material passing;

5. Take measures such as vibration reduction and noise reduction to ensure stable operation of the equipment and low noise;

6. With real-time temperature monitoring and automatic control functions, when the oil temperature rises to the set value, the system will automatically alarm until it stops, thereby effectively avoiding the coil from burning due to excessive temperature rise;

7. The fully automatic type adopts PLC intelligent control to automatically complete all actions such as excitation, feeding, and iron discharge without manual operation, reducing enterprise operating costs, and effectively avoiding human factors that affect the effect of iron removal. The color touch screen is used to set parameters, touch buttons to operate and display working status, and is equipped with a manual operation panel, which is technologically advanced and user-friendly.

Note: The accessories of the system can be customized according to user requirements